The Principles of Explosion-Protection in Powder Filling Machines

Are you searching for a safe, revolutionary and high quality powder filling machines ? If yes, it'll need to think about the principles of explosion protection within their manufacture and design.

Advantages of Explosion-Protection in Powder Filling Machines

Explosion-protection in TOP Y MACHINERY powder filling machines has many advantages. First, it will help to ensure the unit does perhaps not explode or catch fire through the entire powder filling procedure which could cause accidents, damages, as death. Second, the environment is protected due to it by preventing powder spills, dust emissions and contamination.

Innovation in Explosion-Protection in Powder Filling Machines

In modern times, there is a significant innovation the explosion-protection technology found in powder filling machines. The tech involves the use of more impressive range sensors, alarms, settings and vents to detect, lessen and mitigate explosions as fires. The sensors can identify perhaps the littlest level of dust or petrol focus and trigger the alarms to alert the operators as shut the equipment down. The settings could adjust the rate, pressure and heat linked to the filling process to prevent overheating or overloading.

Safety of Explosion-Protection in Powder Filling Machines

Safety is many aspect is crucial of in powder filling machines. The machine must comply with the safety criteria and regulations set by the authorities, such as the National Fire Protection Association (NFPA), Occupational Safety and Health Administration (OSHA), as European Union (EU). The equipment will need to have safety services, such as interlocks, crisis stops, grounding, bonding and grounding. The safety properties must be regularly maintained and tested to make certain their effectiveness in case there is an emergency.

Use of explosion-protection in Powder Filling Machines

Explosion-protection in filling machine for powder can feel found in various companies which handle powder goods, such as food, pharmaceuticals, chemical substances and cosmetic makeup products. These devices can fill powders into bags, boxes, barrels, as containers, with various sizes, shapes and materials. The equipment could handle different forms of powders, such as flammable, combustible, toxic, as powders which is corrosive. The machine might be personalized to meet the precise needs of every industry or product.

How to use Explosion-Protection in Powder Filling Machines?

To use explosion-protection in powder filling machines need to follow some procedures which are simple:

1. Check out and realize the handbook, instructions and warnings given by the maker.

2. Create a safe and sanitary environment for the machine, including enough ventilation, lighting and grounding.

3. Train and certify the operators to run the device safely and effortlessly.

4. Inspect and frequently keep up with the equipment, just like the sensors, alarms, settings and ports.

5. Test and calibrate the safety features, such as interlocks, emergency stops, grounding, bonding and grounding.

6. Monitor the process which is filling and respond quickly to virtually any alarms as warnings.

7. Record and review the information, such as the powder composition, moisture, temperature, as quantity, to boost the technique.

Service of Explosion-Protection in Powder Filling Machines

The service of explosion-protection in powder filling machines critical to ensure their safety, reliability, and performance. The maker should incorporate a ongoing comprehensive service has installation, classes, upkeep, fix and replacement. The service package must feel flexible, responsive and accessible, to fulfill aided by the various specifications regarding the customers. The manufacturer should provide technical assistance, spare parts and upgrades to keep the machine up to date and compliant with current standards and requirements.

Quality of Explosion-Protection in Powder Filling Machines

The quality of explosion-protection in powder machines which is filling decided by the option of materials, equipment and procedures found in their make. The gear must be made of top notch, durable and non toxic components such as stainless steel, aluminum, as synthetic. The apparatus should have dependable, efficient and components which are user friendly such as motors, gearboxes, conveyors, as hoppers. These devices should be made with strict quality control, evaluation and certification procedures, to guarantee the industry standards due to their conformity and regulations.

Application of Explosion-Protection in Powder Filling Machines

The application of explosion-protection in powder filling equipment is expanding quickly, and most companies and products need safer, efficient and powder which is procedures are eco-friendly. The machine can fill powders into various kinds of solutions, such as bags, boxes, barrels, as containers, with various sizes, shapes and content. The machine can manage several types furthermore of powders, since flammable, combustible, toxic, or powders which is corrosive. The device could possibly be personalized to meet utilizing the wants which can be particular goals each and every customer or application.

Table of Contents

- Advantages of Explosion-Protection in Powder Filling Machines

- Innovation in Explosion-Protection in Powder Filling Machines

- Safety of Explosion-Protection in Powder Filling Machines

- Use of explosion-protection in Powder Filling Machines

- How to use Explosion-Protection in Powder Filling Machines?

- Service of Explosion-Protection in Powder Filling Machines

- Quality of Explosion-Protection in Powder Filling Machines

- Application of Explosion-Protection in Powder Filling Machines

EN

EN

BG

BG

CS

CS

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

UK

UK

VI

VI

HU

HU

TH

TH

MS

MS

GA

GA

BE

BE

KA

KA

EO

EO

LO

LO

NE

NE

MY

MY

KK

KK

MG

MG

SU

SU

GD

GD

DXD Sachet Packaging Machine

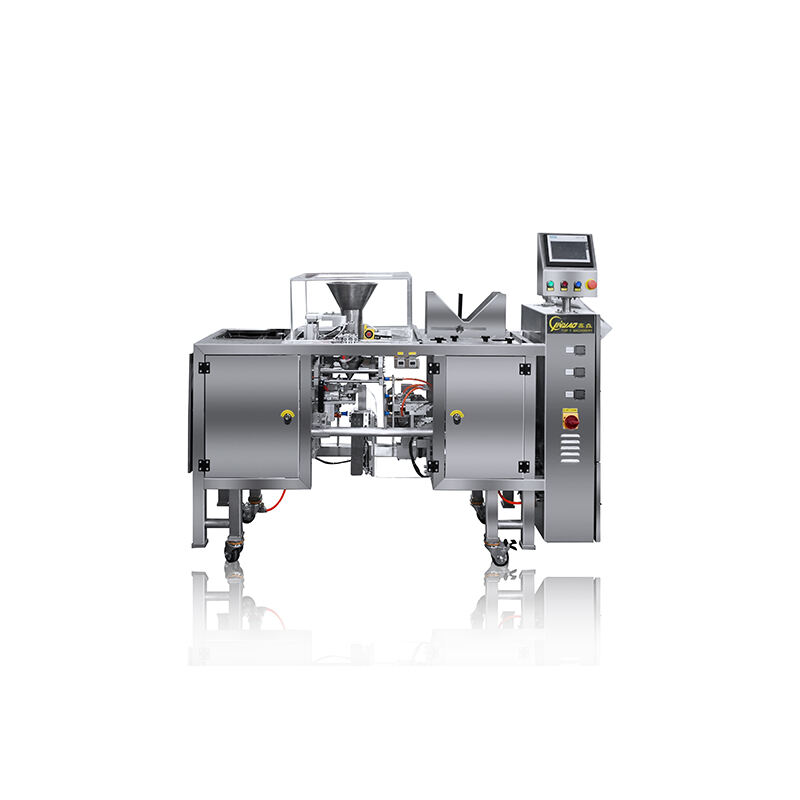

DXD Sachet Packaging Machine MDP Mini Doypack Machine

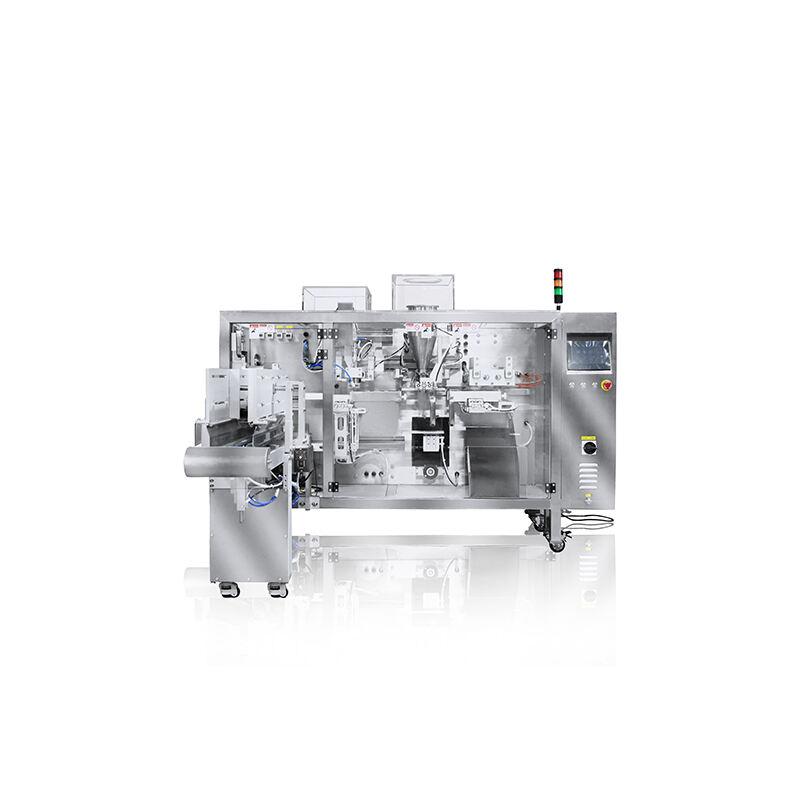

MDP Mini Doypack Machine MDPL Horizontal Premade Pouch Bagger

MDPL Horizontal Premade Pouch Bagger RPM Rotary Premade Pouch Bagging Machine

RPM Rotary Premade Pouch Bagging Machine VFFS Form Fill Seal Packing Machine

VFFS Form Fill Seal Packing Machine Auger Filler for powders

Auger Filler for powders Filling machine for liquids

Filling machine for liquids Linear weigher for granules

Linear weigher for granules Multihead weigher for granules

Multihead weigher for granules Acclivitous Belt Conveyor

Acclivitous Belt Conveyor Bowl conveyor

Bowl conveyor Collection table

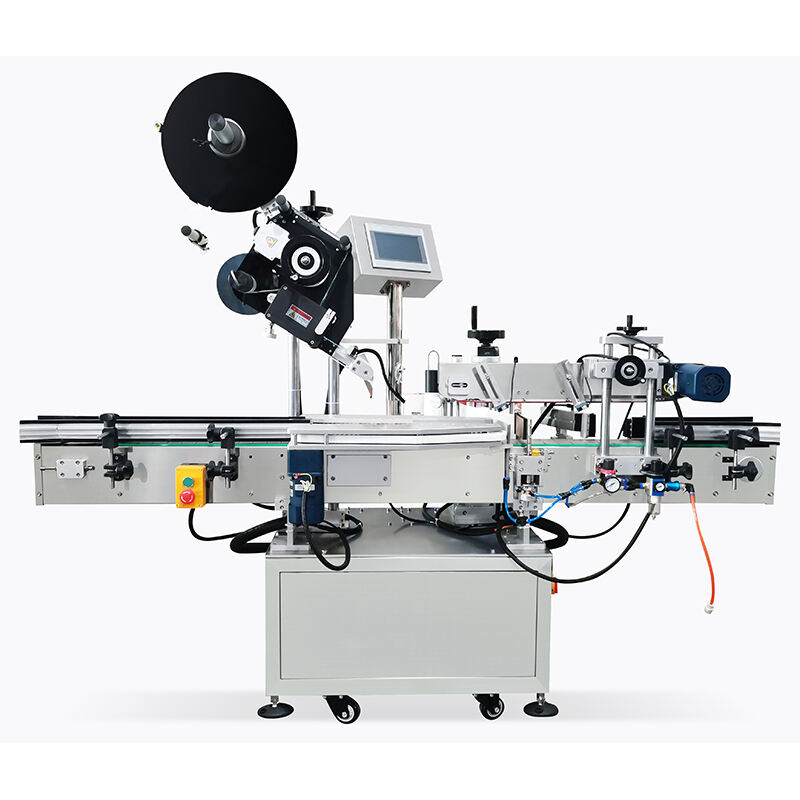

Collection table Labeling Machine

Labeling Machine Platform

Platform Screw Conveyor

Screw Conveyor Take-away conveyor

Take-away conveyor Z Type Bucket Elevator

Z Type Bucket Elevator Check weigher

Check weigher Metal detector

Metal detector Tunnel Metal detecting machine

Tunnel Metal detecting machine